Fluorosurfactant SURFLON

Function·Applications

Leveling·Wetting

By decreasing surface tension, improvement in wetting, penetration, and leveling properties of various substrates can be realized.

Typically, a leveling property of floor wax of the aqueous emulsion type is improved by adding several ten to one hundred ppm of it.

Similarly, by adding to an aqueous emulsion,

a penetration property to fibers and so forth can be expressed. In the non-aqueous system, for example, a leveling property is given by adding to a resist having PGMEA (propylene glycol monomethyl ether acetate) as a main solvent.

The most widely used application of the fluorinated surfactant is in the field wherein this function to improve leveling and wetting properties is utilized.

The floor wax mentioned above is the most representative example; other widely used applications include cleaners in the same cleaning field, and in the fields of coating, pigment, and ink.

Dispersion

For example, a fluorinated surfactant expresses its effect in dispersion of a fluorinated resin such as PTFE (polytetrafluoroethylene).

Firstly, wettability to a fluorinated resin is increased by decreasing surface tension of water or a solvent by a fluorinated surfactant.

Then, the fluorinated surfactant is adsorbed onto the fluorinated resin surface, whereby orientating the perfluoroalkyl group to the fluorinated resin side and the medium-affinity group to the dispersing medium side; and as a result, dispersion stability can be given.

■Applications

PTFE Pigments etc.

Surface Modification

By utilizing a surface migration property of the perfluoroalkyl group, surface modification can be made by internally adding a fluorinated surfactant into a resin.

There are two patterns in expression of the functions: one is to express the function of water repellence and oil repellence by virtue of the surface-migrated fluorine atoms, while the other is to express the function of the non-fluorinated group on the surface by surface-migration of the perfluoroalkyl group of a fluorinated surfactant.

■Applications

Anti-fogging agent for agricultural film Ski-wax Release film etc.

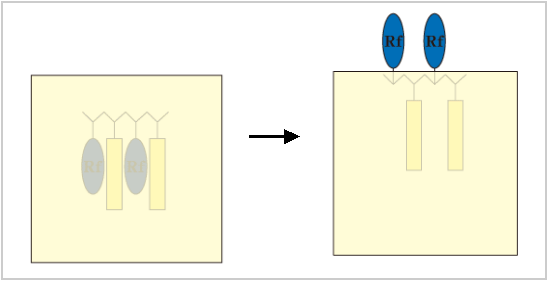

●Example Fluorosurfactant additive in the resin

In the case that a fluorinated surfactant is mixed inside a resin or the like, migration to the resin surface (bleed-out) also occurs by virtue of Rf (perfluoroalkyl group) thereby expressing the function such as water-repellence and oil repellence.

Alternatively, the perfluoroalkyl group is used only to utilize its migration property to surface, whereby application is also possible such that a property of another group that is bonded thereto may be expressed on the surface.

Water and Oil repellent

It is also possible to add a fluorinated surfactant to a composition which is in the state of liquid of an aqueous or a solvent system so that water repellence and oil repellence may be given during the time of its use.

Others

In addition to the above-mentioned, a fluorinated surfactant is applied for various uses such as an emulsifier, a foam stabilizer, and a foaming agent.

Sample

Please contact us if you wish to have the sample.