Fluorocoating agents SFCOAT

Applications

Although a fluorinated coating material surely has general water-repellent and oil-repellent properties, especially SFCOAT has records of specific application to an electronic part as shown below.

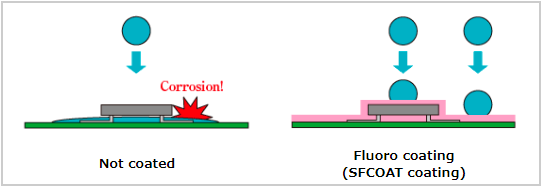

Damp proofing

Owing to a water-repellent fluorinated film, contact with water and moisture, which causes corrosion of a material, can be suppressed. This is widely used in electronic parts and so on, which are used in a high humid environment or installed outdoor.

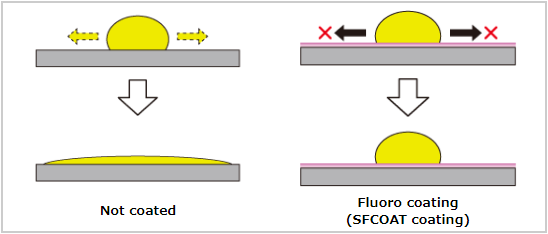

Oil barrier

A lubricating oil is used in a rotational axis and in a sliding part to ease friction. By applying the fluorine coat, diffusion and oozing out of the oil can be prevented.

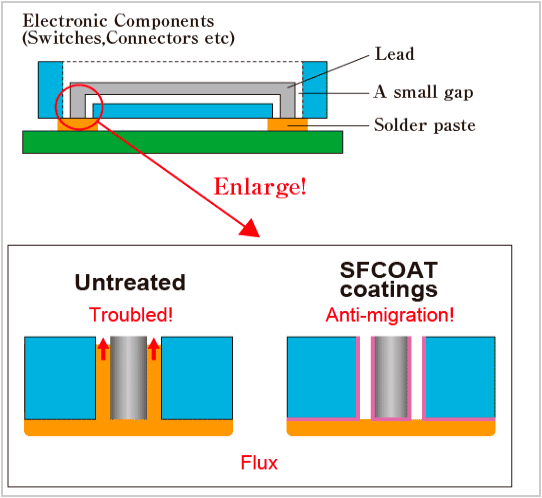

Anti-flux migration

In soldering of an electronic part, flux is always used to activate the bonding surface (this is included in a solder cream).

If this flux penetrates into a part, it causes trouble such as contact malfunction. By using SFCOAT, penetration of the flux can be prevented.

SFCOAT prevents penetration of the flux but does not disturb activation. Because SFCOAT expresses its effect by a thin film, effect to the contact resistance is extremely low. Accordingly, entirety of an electronic part can be treated for use.

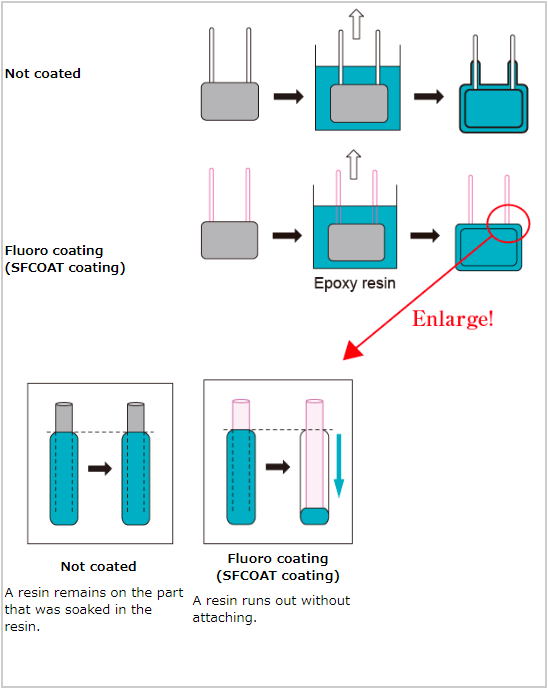

Anti-resin adhesion

During the time of covering with an encapsulating epoxy resin such as a film condenser, attachment of the epoxy resin to a wire lead can be prevented by applying the fluorine coat to the wire lead. Accordingly, a finished part can be obtained without masking and finishing processes.

Sample

Please contact us if you wish to have the sample.