Fluorocoating agents SFCOAT

Fluorocoating agents

In fluorine coating, a well-known example is surface treatment with PTFE (polyterafluoroethylene).

SFCOAT is a surface treating agent, which uses a fluorinated compound having higher water-repellent and oil-repellent properties than PTFE.

The treatment procedure of it is simpler than PTFE; by mere treating with SFCOAT (soaking in SFCOAT or brushing with SFCOAT) a part or a product whose surface is to be processed followed by drying it at room temperature, a fluorine coat having high water-repellent and oil-repellent properties can be formed.

Accordingly, a very small part or a part having a complicated structure can be easily coated by SFCOAT thereby giving a coat that is provided with high water repellence and oil repellence. In addition, a silicone oil, which cannot be readily repelled by PTFE, can be repelled with surety.

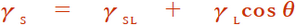

- γL

- Liquid surface tension

- γS

- Solid surface tension

- γSL

- Interfacial tension

YOUNG equation

By fluorine coating, γS (equivalent to surface tension of solid) in the above diagram is dramatically decreased. With this, the value in the left term of Young’s equation is decreased (force to elongate the liquid is decreased) thereby leading to the state wherein it balances with small value of cosθ in the right term of Young’s equation; in other words, it balances in the state of large θ (namely, large contact angle).

Because SFCOAT can lower this γS value (surface tension of solid) as compared with PTFE (polytetrafluoroethylene), high water repellence and oil repellence can be realized.

| Water and Oil repellency | |||

|---|---|---|---|

| Solvent | Surface tension (mN/m) |

SFCOAT (about 11mN/m) |

PTFE (about 19mN/m) |

| Water | about 73 | ○ | ○ |

| Mineral oil | about 30 | ○ | ○ |

| n-hexadecane | about 27 | ○ | △ |

| Octane | about 22 | ○ | ×-△ |

| 2-propanol | about 21 | ○ | × |

| hexane | about 20 | ○ | × |

| Silicone oil | about 20-21 | ○ | × |

Surface tension of the surface that is treated with SFCOAT is approximately 11 mN/m. On the other hand, surface tension of the PTFE surface is approximately 19 mN/m. Accordingly, an organic solvent and a silicone oil that cannot be readily repelled by PTFE can be repelled very easily.

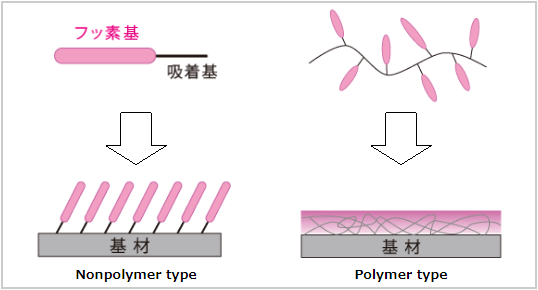

Feature

Surface can be afforded with such properties as water repellency, oil repellency, and fouling resistance by a simple method such as soaking and brushing by using a liquid product that is obtained by dissolving the fluorinated compound in a solvent.

A wide range of products ― from a solvent system of rapid drying to an environment-friendly water system ― are available.

Applications

For explanation and graphic illustration of specific applications, please refer to the link.

If you have an idea of using a fluorinated coating material other than those shown below but cannot imagine which structure or item number is applicable, please feel free to contact us.

-

1.Waterproof Dampproof Water-repellent

Owing to a high water-repellent property, penetration of water and moisture can be prevented. In addition, we are developing a water-repellent coat with which water droplets and the like can run down completely with a slight slope.

◎ Water-proofing treatment of an electric and electronic part

◎ Anticorrosion treatment of an electronic wiring board of an air conditioner and so on

◎ Water-repelling treatment of fibers, leathers, and the like -

Owing to a high oil-repellent property, oozing out and diffusion of a lubricating oil or a grease can be prevented.

◎ Rotational axis of a small motor (PC, HD drive, electric appliance, and so on)

◎ Sliding portion (watch, camera, printer, electric appliance, and so on) -

Penetration of a flux during the time of soldering of an electronic part can be prevented. By treating an electronic part and a wire lead, penetration (crawling up) of a flux into a part can be prevented.

◎ Prevention of flux penetration into a small switch and a connector -

This can be used to prevent a resin for encapsulation of an electronic part and so on from attaching to an unwanted site or from diffusion.

◎ Prevention of attachment of an epoxy resin of a film condenser -

5.Antifouling

This can be used as an antifouling agent because various kinds of fouling liquids (water fouling and oil fouling) can be not only repelled but also cleaned easily.

Sample

Please contact us if you wish to have the sample.